ST. LOUIS — The U.S. Chemical Safety and Hazard Investigation Board (USCSB) released a video Wednesday outlining new details on the deadly 2017 boiler explosion at the Loy-Lange Box Company in St. Louis.

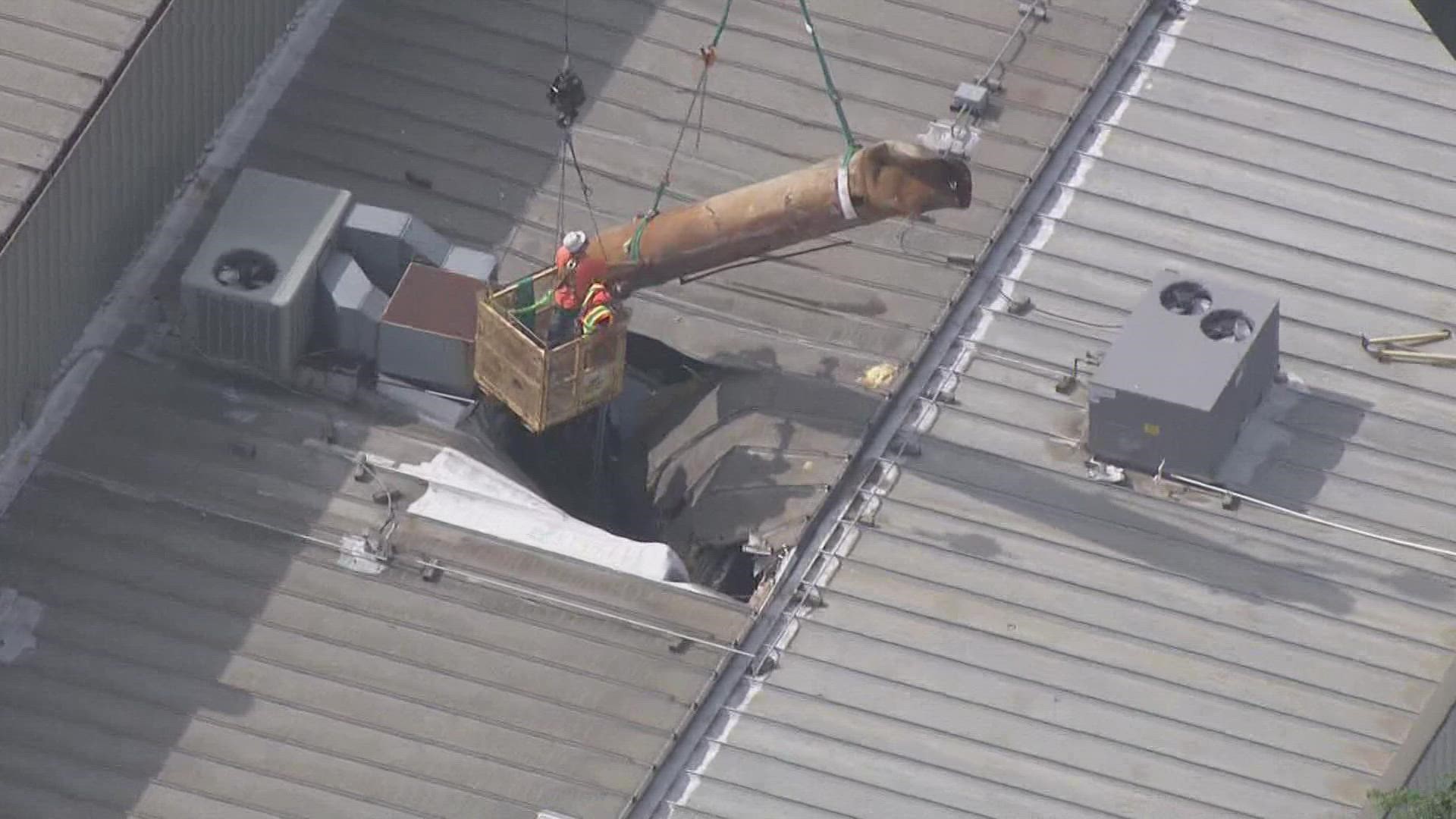

On the morning of April 3, 2017, a boiler at the Loy-Lange Box Co. exploded, launching debris the size of a full-sized van more than 500 feet away. That debris came crashing through the roof of Faultless Healthcare Linen. Loy-Lange employee Kenneth Trentham and three Faultless employees on their first day of work — Clifford Lee and newlyweds Tonya Gonzalez-Suarez and Christopher Watkins — were killed.

The 17-minute video goes through the details of the investigation into what caused the explosion that left four people dead. Investigators said a part of the steam system called a semi-closed receiver (SCR) was not properly repaired, eventually leading to the deadly failure.

The video said the incident could have potentially been avoided if inspections by the National Board of Boiler and Pressure Vessel Inspectors or a St. Louis city inspection caught the issues.

"Prior to its failure, Loy-Lange ran the pressure vessel normally despite knowing that it was leaking," the video said. "It was a safety emergency that unfolded in plain sight."

Issues at Loy-Lange

Investigators said employees reported a leak at the bottom of the CSR the Friday before the explosion. They called a welding company to inspect it, but the company was not available until the following Monday.

The system continued running the rest of the day Friday, and employees restarted the system normally the following Monday. A little more than an hour later, the explosion sent the 14-foot-tall part flying through the air and into a nearby business.

Inspectors said the way the workers operated the system over the years led to more rust generation than normal. Allowing oxygenated water to be processed by certain parts of the system resulted in rust formation and corrosion.

A previous leak was repaired in 2012, but the video said only part of the damaged equipment was replaced, leaving a ring of corroded metal that eventually contributed to the explosion.

In the video, investigators went on to say the business lacked proper safety systems. They said if employees understood the potential danger of the system, they likely would not have operated the system while it was leaking or operated it in a way that caused the rusting.

The 2012 repair

Inspectors said the repair was made by a licensed company, but the repair did not follow the proper steps. The repair was approved by an inspector with the National Board of Boiler and Pressure Vessel Inspectors, but the inspector did not look at the part before the repair was conducted or observe the repair while it was happening.

"Had the repair inspector seen the repair in progress, the inspector might have detected and refused to accept the inappropriate repair, which could have prevented the incident," the video said.

The video said the National Board of Boiler and Pressure Vessel Inspectors has made changes to its inspection process, but the USCSB inspectors suggested more changes.

The suggestions included updating inspection requirements to require inspection of damaged parts before a repair is approved or observing the repair process in person.

St. Louis inspections

The video said the damage could have also been detected during inspections of the system.

The city requires annual inspections of systems with pressure vessels, but the company never applied for an installation or repair permit for the pressure system, meaning the city didn't even know the system was in the building.

The city did know there were steam generators at the facility, but it hadn't inspected them since 2010.

"Had the city performed more regular inspections of the Loy-Lange steam system, it could have identified the unregistered SCR, sealed it from operation and ensured its inspection, potentially catching the corrosion hazard before the vessel failed," lead USCSB investigator Drew Sahli said in the video.

The city has also made changes to inspection requirements, but the USCSB suggested more steps.

The investigators suggested the Board of Aldermen change the city's mechanical code to adopt national standards for in-service inspections of boilers and pressure vessels and require the inspections be conducted by a National Board of Boiler and Pressure Vessel Inspectors commissioned inspector.

You can watch the full video below or by clicking here.

More than a dozen victims, including the families of the killed workers, reached a $47 million settlement in August of 2019 with the six companies named in a lawsuit over the explosion.

Kickham Boiler and Engineering, Chicago Boiler Company, Aquacomp Water Treatment Services, Loy‐Lange, and Arise Incorporated will pay a combined $47 million to those injured and the families of those who were killed in the explosion.

To watch 5 On Your Side broadcasts or reports 24/7, 5 On Your Side is always streaming on 5+. Download for free on Roku or Amazon Fire TV.